Researchers at the Columbia University School of Engineering and Applied Science, are working on a technique that lets printing with different materials using additive manufacturing processes feasible.

Additive manufacturing—or 3D printing—uses digital manufacturing processes to fabricate components. Over the past decade, the field has experienced a 20% year on year growth rate, says the university.

“Now, let me ask you,” Hod Lipson, James and Sally Scapa Professor of Innovation (Mechanical Engineering) with the university asks. “How many products are made of just one material?”

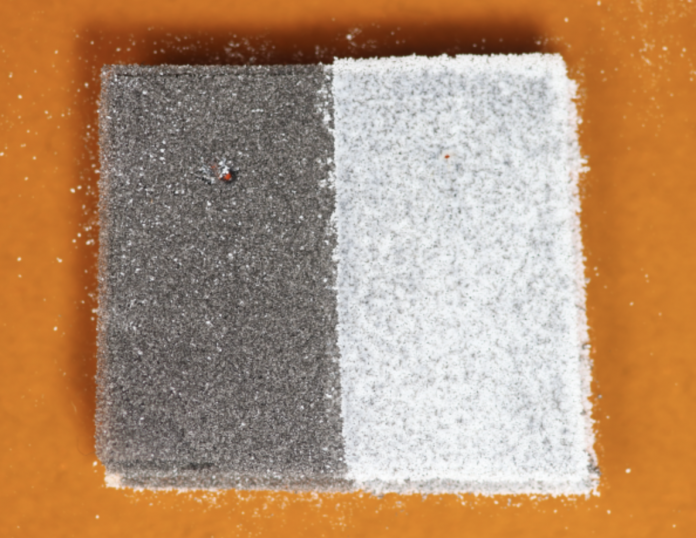

The widely-used selective laser sintering (SLS) additive manufacturing process, prints parts out of micron-scale material powders using a laser; the laser heats the particles to the point where they fuse together to form a solid mass. The catch is that SLS technologies have been limited to printing with a single material at a time: the entire part has to be made of just that one powder, according to the university.

By inverting the laser so that it points upwards, researchers at the university are able to use SLS—at the same time— for multiple materials.

The researchers are now experimenting with metallic powders and resins in order to directly generate parts with a wider range of mechanical, electrical, and chemical properties, according to a statement by the university.

[Image courtesy: Columbia University]